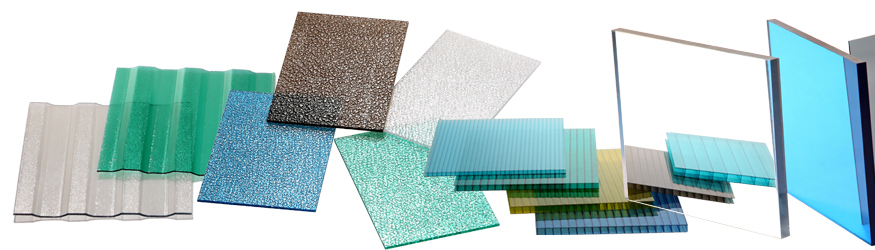

Engineering and construction materials for displays and varied applications come in many forms and types and one popular product that’s gaining is polycarbonate sheet.  Polycarbonates, especially those sheets that are scratch resistant or finished with hard coating are now favored construction and display materials thanks to its durable construction and flexible nature that allows it to be melded, worked or thermoformed. And since many companies now offer anti-scratch coating as a value added service to polycarbonate sheets, scratch resistant polycarbonates are now highly sought after offering better value for money.

Polycarbonates, especially those sheets that are scratch resistant or finished with hard coating are now favored construction and display materials thanks to its durable construction and flexible nature that allows it to be melded, worked or thermoformed. And since many companies now offer anti-scratch coating as a value added service to polycarbonate sheets, scratch resistant polycarbonates are now highly sought after offering better value for money.

Anti-Scratch Polycarbonate Sheets for Improved Protection

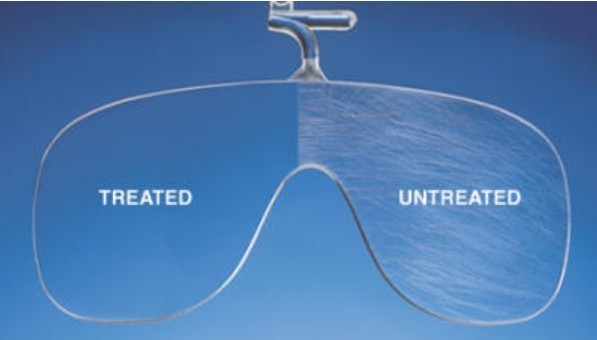

Polycarbonates are tough materials often used in engineering and designed to be optically transparent. Thanks to these properties, polycarbonate sheets are favored materials in a number of applications from automotive engineering and consumer electronics. Polycarbonates are often used in making CDs, DVDs and CD-ROMs and also a great material for automotive applications.  These sheets are also used in commercial applications, particularly for display purposes. Although polycarbonates are tough and highly flexible, it has one weakness- polycarbonate sheets are soft plastic which are prone to damages or scratches. This is where anti-scratch coating comes into the picture. With the application of an anti-scratch coating on polycarbonate sheets, a variety of custom materials can be produced for different applications including scratch-resistant sheets, anti scratch lens and anti scratch film.

These sheets are also used in commercial applications, particularly for display purposes. Although polycarbonates are tough and highly flexible, it has one weakness- polycarbonate sheets are soft plastic which are prone to damages or scratches. This is where anti-scratch coating comes into the picture. With the application of an anti-scratch coating on polycarbonate sheets, a variety of custom materials can be produced for different applications including scratch-resistant sheets, anti scratch lens and anti scratch film.

The use of anti scratch polycarbonate sheet can work in the police force.

Traditionally, the protective visors, prison windows and riot shields are simply made from tough polycarbonates. But constant use and abuse often damage the surface of plastic making these tools and equipment unattractive. But with the addition of anti-scratch coating, the materials become scratch resistant with improved abrasion resistance that can withstand constant use and the application of corrosive cleaning agents.  In short, the anti scratch polycarbonate sheets with hard coating makes the duty of maintaining peace and order stylish and fun.

In short, the anti scratch polycarbonate sheets with hard coating makes the duty of maintaining peace and order stylish and fun.

Polycarbonates with Anti-Scratch Coating Delivers in Retail Environment

Polycarbonates with anti-scratch coating also work in the retail environment. Polycarbonates can be used as display cases to show off the merchandises and other products for sale. But constant use, touch and fingerprints will leave the display ugly to look at.  This can be addressed with the application of an anti-scratch coating to make anti scratch polycarbonate sheet. No matter how many hands will try to touch the display or marvel at the display, store supervisors will remain confident that the display will retain its looks thanks to the addition of anti scratch film. The use of anti scratch film and anti-scratch coating can also work in the food and restaurant industry.

This can be addressed with the application of an anti-scratch coating to make anti scratch polycarbonate sheet. No matter how many hands will try to touch the display or marvel at the display, store supervisors will remain confident that the display will retain its looks thanks to the addition of anti scratch film. The use of anti scratch film and anti-scratch coating can also work in the food and restaurant industry.  Display cases and containers are usually made from polycarbonates and when these cases are applied with anti-scratch coating, the display retains its cleanliness and optical clarity, thus adding to the appeal of food and delicacies to be served.

Display cases and containers are usually made from polycarbonates and when these cases are applied with anti-scratch coating, the display retains its cleanliness and optical clarity, thus adding to the appeal of food and delicacies to be served.

Polycarbonates are tough, reliable and highly flexible materials but these can still be improved. What you can do is to apply an extra layer of anti-scratch coating or anti scratch film to create a reliable, dirt-free anti scratch polycarbonate sheet.

Uncategorized

During the formulation or designing of any business plan, its desired goal is to have good returns/ revenue, satisfied clients coming back again and again with their friends.

Providing quality products is important for the success of a new business. The new venture should satisfy the customer’s demands. It must bridge the gap that existed in the market.

One thing to put in mind is the fact that, any type of business will require commitment, dedication and working smartly.

Start a polycarbonate shop is the same,you need to consider too many factors,and below are 10 important factors you need to consider in the whole process for the new polycarbonate shop:

1.Source better quality polycarbonate raw materials

For effective running of a polycarbonate shop, the dealer should look for desirable, reliable and a cost effective source of the materials.

Take for instance, buying the polycarbonate panels and profiles from suppliers like Excelite ,bayer,sabic and so on.

It’s advisable for the dealer to do adequate research on the supplier available in the market before starting on the business.

With the research information the dealer will be able to make sound and effective decisions on the suppliers to contact and seek to develop a strong supplier relationship.

It’s also advisable to have a wide selection list of suppliers as this will help in ensuring availability of the materials as well as quality services from them and this is what you need to show your customers.

2 : Source of funds

The polycarbonate business like any other business requires some amounts when starting. You need to have enough money to take you for several months. A new polycarbonate shop will not guarantee profits or returns within the first few months.

Despite all these, you will have to pay for the transportation, establishing the business and administrative costs. In short, you will have to inject more money in the polycarbonate sheet business to make good foundation.

It is important that you evaluate the sources of funds and some of the sources to consider include:

1. Equity financing

Here, you will have to exchange a section of the ownership of the business for financial investment in the polycarbonate business.

This involves permanent investment in the shop. These may include personal savings, borrowing from friends and relatives, venture capital, angel investors, government grants, etc.

2. Debt financing

This is where you borrow money with an aim of repaying it with the interest within a given period of time. You can approach friends and relatives or commercial lenders such as banks.

3. Lease

This gives you an opportunity to obtain the assets for the new polycarbonate shop without necessarily opting for debt or equity financing.

As you look for the source of funds, it’s important to consider the terms and conditions of repayment. It should not be one that will derail the new polycarbonate venture from expanding. If you have enough savings, then it will be better.

3.Location of the shop

A polycarbonate shop should be situated in a place that its customers easily access it. It should be near areas where polycarbonates products are used.

Ideal places can be in towns where a large number will be ready to buy any of the products. You need to establish whether there is demand for the product or not.

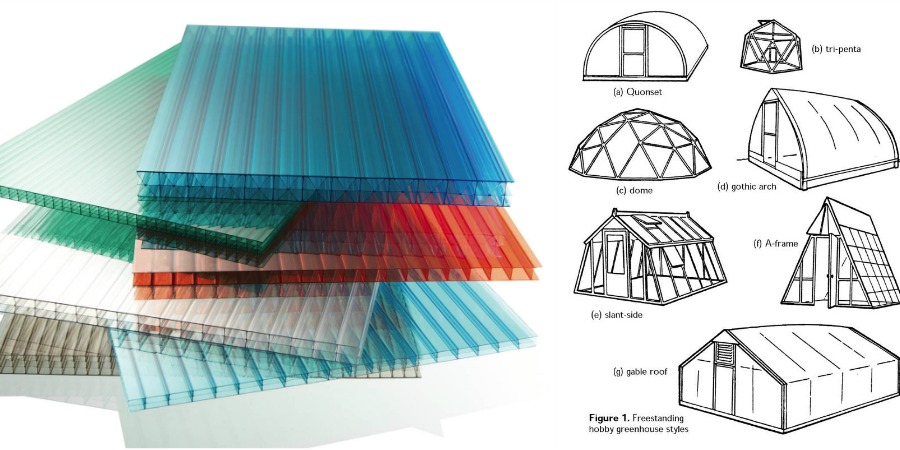

For instance, in most high end places within towns, the demand for multiwall polycarbonate sheets is high. This is because they use them to make swimming pool covers,greenhouse,roofing etc. This could be a better location.

Opening a subsidiary company for the greenhouse polycarbonate panels can also be profitable. When you have a subsidiary company in such places, you will save on the transportation cost of the finished products. This will ensure that you deliver the products not only faster, but at a relatively cheaper cost.

It is also good to locate the shop near other shops that sell/ deal with other building materials or being close to other complementary shops.

This will help the consumers when they are doing their buying. For a polycarbonate shop, the customers are likely to need loading areas/ parking space.

It should be put into consideration when looking for a shops location.

In relation to the above, the shop should be in a good looking place- a good appearance. It is also good to note that a dealer should take care of the location’s regulations and legislation procedures as well. These laws can in a great way limit the growth and prosperity of the shop.

It is important to conduct an environmental impact assessment and get the necessary certificates to approve the construction of the polycarbonate shop.

This is very crucial if you would wish to conduct other processes such as shaping the polycarbonate sheets. It is also wise to have acceptable waste disposal procedures. Waste is inevitable and the best we can do is to adopt better waste disposal procedures.

4.Conduct a market analysis

Consumers look for unique products. The same known product sold in a slight different version than what is in the market.

In the already existing market, how are the corrugated, textured, sheets, embossed, multiwall or the solid carbonates sold?

Already, there are people doing this kind of business, so how will you ensure that you dominate this market?

Product differentiation and quality manufacturing process. The consumers should see this practically and they should be convinced.

There is no consumer who believe in rumors. The parent company must have a polycarbonate testing laboratories. Since polycarbonate panels is vulnerable to ultraviolet radiation, the consumer must be convinced beyond reasonable doubt that all polycarbonate are UV protected. They are also abrasion resistant.

Could they be repackaged or sold in smaller sizes or be sold to a customer’s specification?What is it that the polycarbonate customers need for them to feel satisfied? In order to make it in the polycarbonate market it would be advisable to understand the following:

1. The aggressiveness of the competition

2. the number of the competitors

This will help one equip him well before going into the market,the trade potential for various lines of trade in the polycarbonate market. All these will help your shop to stand out from the rest of your competitors.

A market analysis is crucial to a firm that would wish to succeed in the market. When you establish a shop without conducting market analysis then you should expect any prosperity.

5.Competent employees

In the polycarbonate shop the employee should be well informed of the products they are selling. Customers need someone with clear, concise information about the product they are being sold.

Employees can be a tool of helping in making large sales by making it known to consumers the large and versatile use of the products they stock.

The employees should be conversant with all the end products of polycarbonate sheets. That is, the swimming pool enclosures, greenhouses, roofing sheets or even as the sound barrier panels. This is crucial whenever a customer asks for a quote for a given finished product.

It is common to find that a customer wishes to construct a polycarbonate skylights, but he or she does not know the quantity of the sheets required. The employees should be able to give a correct quote of the same.

6.Offering after sale services

Polycarbonates require skills to install it in whichever place they are to be installed. A dealer can be linking customers with expert to help them installing them – the polycarbonates.

This will create to the customers a sense of being held highly and being thought of. They can also offer after sale service of transporting customers merchandise maybe within a radius of several kilometers from the shop.

You need to lay the foundation for this and conduct the feasibility studies here. Your customers will be happy if they buy a product from a shop and you offer to transport and install the sheets for them. It is a good way of expanding your territory, especially for a new shop.

7.Shop’s layout

All customers like to be impressed by the general look of a shop and the polycarbonate customers are no exemption.

All the merchandise that the shop is selling should be well shown to the customers. Additionally, materials relating to each other should be kept next to each other too.

You should show case the potential that is available in the polycarbonate shop. Try to display the photos of you past projects. You need to avail customer testimonials as well. This will make the consumers to have confidence in your shop.

8.Aggressive marketing

Customers have become quite busy and they want to be supplied with information regarding their requirements even before they need it.

The shop need to conduct aggressive marketing to make it known to potential customers what they offer and where they are found.

This should be done through advertisement and promotional sale. In addition, online marketing will go a long way in increasing the company’s revenue and enlarging its client’s base.

The shop could also consider having an online store where it will be getting orders from the customers is responding to their directives.

9.Formulate a business plan.

In order to have a line to follow,it would be advisable to have a well laid down business plan to help as the vehicle to move on.

The plans will be the path through which the shop will be moving on and within it are the set / desirable goals for the shop.

The business plan should capture all the vital aspects of the business, from the supply, delivery and maintenance procedures.

10.Risk management.

All businesses have their share of a certain risk. If could be theft, fire or any other risk that can befall the polycarbonate shop.

For this reason it would be necessary to seek an insurance policy that would best fit the shop considering what is being stocked.

In summary, there are very many factors you need to consider before you contemplate of starting a new polycarbonate shop.

You need to consider all the factors above to ensure that the business gets a good foundation. When you ignore any of these factors, then you will be sure that the business may not do well in the future.

All factors mentioned above complement each other. You need to blend them together since they will ensure that the new shop is sustainable.

There are key issues highlighted in this article, first the availability of both the supply and demand. Where do you get the products and who are the targeted customers.

This narrows down to market research. Two, the availability of funds. The terms and condition must be friendly.

Lastly, is how can you run the enterprise. That is, take into account how you expect to distribute product and the after sales services.

The risk management skills also form a crucial aspect in this stage. With all these in mind, you will be having a higher probability of success.

This can be a difficult task, I must admit however, you can get advice from the polycarbonate experts. If you are going to purchase polycarbonates from Excelite, then company can equip you with some of these skills. Feel free to contact them.

Always remember this quote by Thomas Edison: The value of an idea lies in the using of it. I believe you have the right idea, what are you waiting for?

Like most polycarbonate materials, excelite polycarbonate is apparently being used to replace glass in most applications such as in agriculture, public buildings, industries, etc. This has been due to their high impact strength, charming appearance, lightweight, UV protection and better light transmission. In fact, the impact strength of polycarbonate sheets is about 200 times better than that of the ordinary glass. However, it is important to note that polycarbonates lack a very essential property; being scratch resistant. In the recent past, there has been a lot of research going on to develop anti-scratch polycarbonates. So far, this has been achieved by using a hard coating which makes their surface abrasion and UV resistant.

The anti-scratch polycarbonate sheets which have been formulated with hard coating protects the material against chemical attack and scratching; guarantees optical clarity; protects it against the hostile outdoor weather; becomes graffiti resistance and makes it easier to clean. Normally, these materials are used in areas which experience high traffic. This coating extends its service life; saves you from expensive maintenance procedures and enhance customer usage experience.

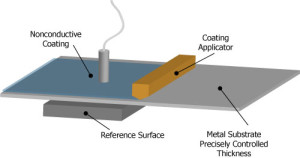

For a long time, abrasion resistant coating has been used to protect polycarbonate sheet from scratch besides achieving all the desired qualities. Normally, the term hard coating can be used to refer to abrasion resistant coatings. These coatings come in the form of a very thin film which is optically clear and it can improve the decorative and functional properties. It is advisable to go for those hard coating materials which are durable and flexible.

The choice of a hard coating for any anti-scratch polycarbonate material will depend on the nature of the application. For instance, a polycarbonate sheet which is used in roofing, observe window, indoor partition, sound barrier and outdoor windows should meet the following criteria: an impact strength of about 850J/m; light transmission of between 80% and 90% for different thickness; thermal expansion of 0.065 mm/moC; service temperature of between -40°C and 120°C; tensile strength of >60N/mm2; natural flexibility of about 100N/mm2 and an elongation at break of >100% just to highlight some key features. Choosing the right coating is such a technical thus; it is advisable you seek help from a qualified individual.

Every hard coating which is available in the market has its unique technical data which blends with a specific application. For instance, two products such as SafeCoat 401 and SafeCoat 404 can protect polycarbonate sheet from scratch, however; the degree of this protection will be dictated by the chemical composition of each hard coating material.

The 401 is mainly used in applications where maximum impact resistance is of a priority alongside resistance to abrasion. On the other hand, the 404 is mainly used in applications where the glossy effect is of essence alongside scratch resistance.

You should not assume that by purchasing an anti-scratch polycarbonate sheet, then there will be no need of using the recommended cleaning procedure and detergents; you must adhere to the manufacturers’ guidelines. It is a sure way to optimize its service life.

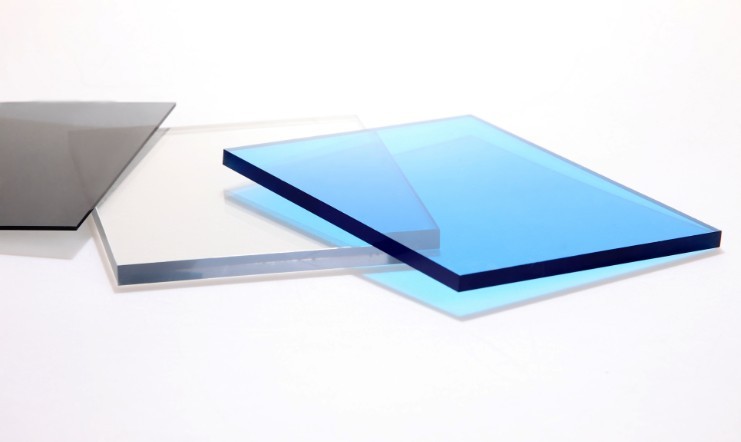

Acrylic sheet

Overview

Excelite Acrylic sheet was founded in 2009, insisting in developing high end and high quality products. Excelite Acrylic has both casting and extrusion processing equipment. The products have super excellent transparency, excellent weather ability, good processing properties, and excellent overall performance. Meanwhile, Excelite could jointly develop with customers for end product, provides one-station services.

Features:

- Excellent transparency, transmittance 92%

- Excellent weather ability

- Anti-aging properties performance

- Good processing properties for both machining and thermo forming

- 10 years warranty

- ease of cleaning

Potential Applications

- Sound Barrier

- Skylight

- Light box, Lampshade

- Signs

- Display Stand

- Protective mask

- Crystal Furniture

- Bathtub

- Aquarium

- Light guide plate

Standard Specification

Extrusion Sheet

|

Thickness (mm) |

Standard Width (mm) |

Standard Length (mm) |

Specific Gravity(kg/m3) |

Standard Colors |

| 1.5;2.0 | 1200;1220 | 1200;1220 | 1.2 | clear |

Casting Sheet

|

Thickness (mm) |

Standard Width (mm) |

Standard Length (mm) |

Specific Gravity(kg/m3) |

Standard Colors |

| 2.0~50.0 | 1110~2160 | 1780~3160 | 1.2 | clear |

*Other dimension and color are available with a special order, subject to a minimum order

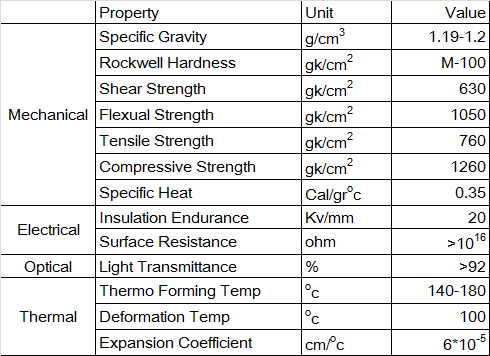

Property

Excelite Embossed polycarbonate sheet

Overview

Embossed PC solid sheet treating with texture or pattern is embossed on its surfaces. molybdenum wire By the texture diffuses the natural light which streams in and ensures uniform dispersion of light over a large scale area that can prevent glare. It also has ability to perform in wide range of temperature up to 100 degree Celsius makes the embossed sheets excellent for light fixtures that hear up after long usage. It is more used mainly in the partition with beautiful decoration effects

Features

- protect Privacy with its translucent surface

- High Impact Resistance, practically unbreakable

- 10 Year Warranty

- Lightweight

- Anti-ultraviolet, delay aging

- Large range of sheet sizes & thicknesses

- High temperature resistance

- light transmission – 40% to 72%

Potential Applications

- Industrial Roof Lights

- Industrial wall cladding

- Privacy Glazing

- Sky lights

- Domes, Canopies & Pyramids

- Light Diffuser in architectural light fittings

- Partitions & Ceilings

- Paneling

- Embossing & Engraving

- Bathroom

- Upholster

Standard specification

|

Thickness(mm) |

Standard length(mm) |

Standard Length(mm) |

Standard Colors |

Embossed Styles |

|

1.8-12 |

1200-2100 |

5800mm Thickness≤ 3mm no limited |

clear, |

diamond, rain-drop, lichee, |

Property

|

Physical Properties |

Method |

Condition |

Metric |

|

Specific Gravity |

GB/T 1033 |

All thickness |

1.2 g/cm3 |

|

Water Absorption(24Hr) |

GB/T 1033 |

24H@ 23? |

0.30% |

|

Effect of soundproof |

GB/T 1033 |

10mm |

32dB |

|

Mechanical Properties |

Method |

Condition |

Metric |

|

Tensile Strength |

GB/T 1040 |

60.3MPa |

|

|

Tensile Elongation, break |

GB/T 1040 |

108% |

|

|

Elongation at Break |

GB/T 1040 |

>90% |

|

|

Elongation at Yield |

GB/T 1040 |

6% |

|

|

Coefficient of linear expansion |

GB/T 1034 |

0.000063??¹ |

|

|

Notched impact strength of the beam |

GB/T 1843 |

6.2KT/? |

|

|

modulus of elasticity in static bending |

GB/T 9341 |

2400 Mpa |