Advantages

Components:

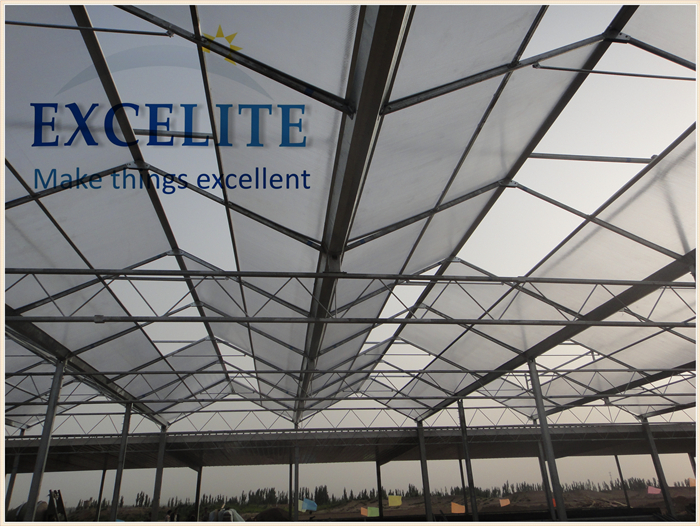

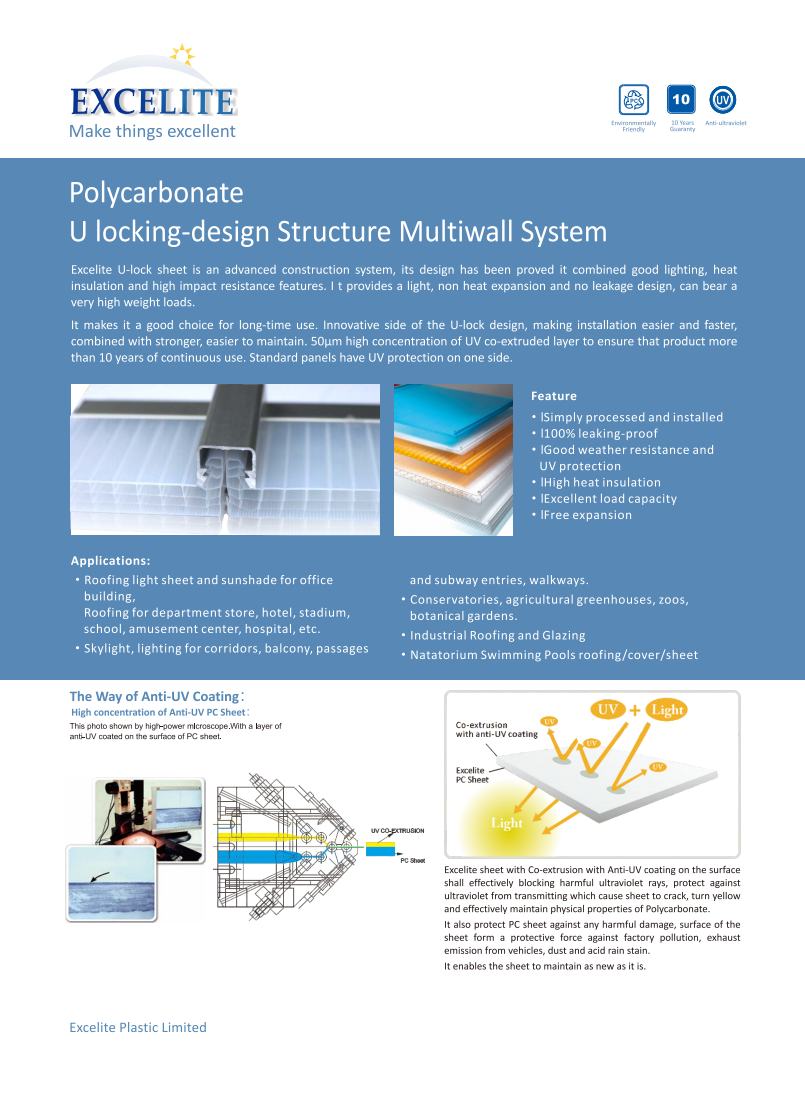

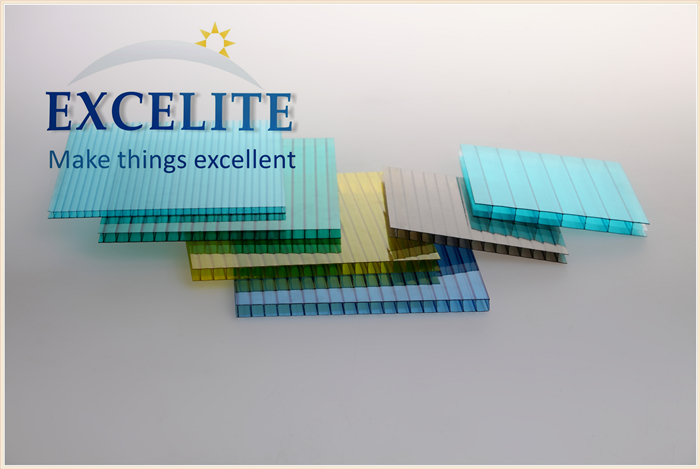

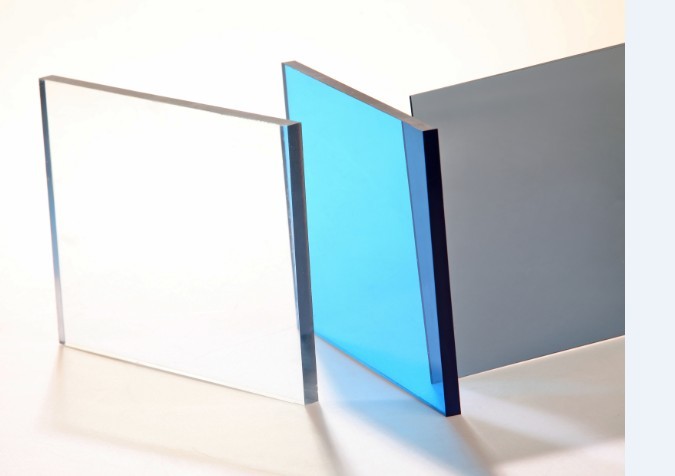

3.Glazing: Twin-wall polycarbonate thermal glazing, 8mm,

1) protects the exterior surfaces from damaging ultraviolet rays;

2) captures infrared light to create solar energy, thus increasing your pool’s temperature by up to 20°;

3) is specially treated for antifogging to prevent condensation build-up and improve light transmission.

4) Anti Dust Sealer: Anti Dust Sealer will prevent mold, algae, dust and insects from entering the channels, ensure the clarity of multi-wall glazing. It is moisture and temperature resistant and enables continuous drainage of condensation.

5.Track: Reinforced, clear anodized aluminum tracks designed for smooth traction. You can open or close the enclosure in less than a minute. Our tracks provide security from high wind and snow load conditions, while remaining foot friendly.

6.End panels: Enclosure includes two end panels. One end panel comes with a 36 inch patio door.

7.Hardware & Fasteners: Excelite™ use only stainless steel and aluminum hardware and fasteners throughout the entire enclosure.

More details,you can check our products swimming pool cover on our company website.

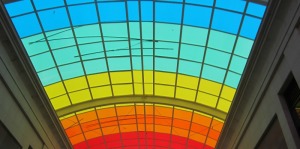

Pictures: